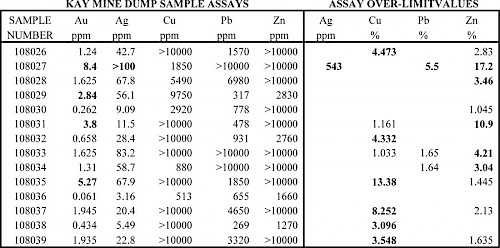

March 14, 2018 - Bridgewater, NS - (TSX Venture:SSE) - Silver Spruce Resources Inc. ("Silver Spruce" or the "Company") is pleased to announce that it has received its second batch of assays of mineralized rock samples taken from the development/production dumps at the Kay Mine in Arizona. This second batch consisted of fourteen additional samples taken for data verification purposes to confirm the tenor of mineralization reported by Exxon Minerals Corporation and previous developers of the mine. The samples consisted of volcanogenic massive sulphide (VMS) and sulphide-bearing material. Assay values from these samples are listed in the table below with their respective over-limit values.

March 2018

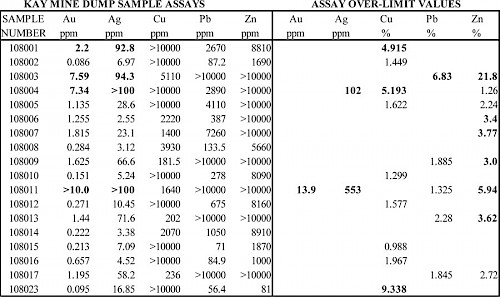

"We continue to be impressed with assay values from the dump material that was taken from underground workings when the mine was being developed for production, prior to 1957," stated Karl Boltz, CEO of Silver Spruce. "Together, with the initial twenty-five samples assayed in December 2017, shown below, these positive assay results are part of our ongoing efforts to confirm the resource stated by Exxon Minerals, in 1982, after ten years of advanced exploration, confirmation drilling and resource estimation at the project."

First Batch of Assays Released on December 7, 2017

The majority of the sulphide-bearing samples were collected from the historic development/production dumps at Shaft #4. It should be noted that the grab samples are selective by nature and values reported may not be representative of mineralized zones. Examination of the mineralized material indicated disseminated to semi-massive to massive sulphides, consisting of pyrite, sphalerite, chalcopyrite and galena in banded, lenticular and breccia to replacement textures. Compositional layering from <1mm to 2cm in thickness were comprised of pyrite-dominant and base metal-bearing units. Coarse-grained pods and veinlets of chalcopyrite and sphalerite from 1-3cm also infill silicified rhyolite breccias.

Kay Mine Background

The Kay VMS deposits were developed for production on eleven levels and accessed via four shafts prior to 1957, when the pumping station was damaged and the mine was flooded. Records obtained by Silver Spruce indicate that approximately 1,550 tons of ore grading 5.6% Cu, with individual bulk samples from 2.95-9.47% Cu, with Pb, Zn, Au and Ag credits, was mined on the 250 foot and 500 foot levels from 1949 to 1953, and shipped to various smelters in Arizona and Texas. An estimated 15,000 tons of low grade material was reported on the surface dumps in 1956. The last production of 70 tons grading 5.7% Cu selected from the surface dumps was shipped by a private owner in 1966.

In 1972, Exxon acquired the project with the goal of commencing production of the known high-grade Cu-Zn-Pb-Ag-Au ores. Exxon's internal geological reports referred to the mineralization defined by drilling and historical underground exploration, under the then existing mining standards, as "proven and probable ore" of 6.4 million tons with a potential of over 20 million tons. These resource estimates and terminology are to be considered historical and not compliant with current NI 43-101 guidelines.

The Company believes that the previous work conducted by Exxon was completed to a high standard of competency and credibility. Silver Spruce is developing exploration programs to document the tonnage and grade of the Kay mineralization and develop a resource estimate to conform to the present National Instrument 43-101 standards.

Silver Spruce also is investigating the cost, logistics and permitting requirements to de-water the mine workings for direct access to the mineralization.

Quality Assurance and Quality Control

Samples were collected by the Company's QP, packaged and shipped in sealed pails by commercial carrier to northern Washington, and delivered by the QP to British Columbia for sample description and preparation of the assay splits. The rock samples were sawn, or split as required, with a representative cross section or portion bagged and sealed in packages by the QP and delivered by commercial carrier to ALS Global's sample preparation facility in North Vancouver. The sample pulps were transferred internally to ALS Global's analytical facility, also located in North Vancouver, for analysis. ALS Global in North Vancouver, British Columbia, Canada, is a facility certified as ISO 9001:2008 and accredited to ISO / IEC 17025:2005 from the Standards Council of Canada. Photographs of the individual rock samples, as -received and sawn faces, were collected from each sample prior to shipment, and will be made available on the Company web site in due course.

No independent or in-house quality control samples (blanks, standards, duplicates) were inserted into the batch of twenty-five grab samples or the second batch of fourteen samples. ALS Global conducts its own internal QA/QC program of blanks, standards and duplicates, and the results are provided with the Company sample certificates. The results of the ALS control samples were reviewed by the Company's QP and were within acceptable tolerances. All sample and pulp rejects are stored at ALS Global pending full review of the analytical data, and future selection of pulps for independent third-party check analyses.

The samples were crushed to 70% passing 6mm (-10 mesh) and a split of up to 250 grams was pulverized to 85% passing 75 micrometres (-200 mesh). Each pulp was then submitted for analysis by 4 Acid Digestion followed by Inductively Coupled Plasma Mass Spectrometry (ICP-MS) multi-element analyses (ALS Code ME-MS61, 48 elements). All base metal analyses that reach the over-limits of ME-ICP61 are re-analyzed with an Ore Grade method. Over-limit Cu (>1%), Pb (>1%), Zn (>1%) and Ag (>100ppm) samples are analyzed by Ore Grade 4 Acid Digestion followed by Ore Grade Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES) for Pb (ALS Code Pb-OG62) and Ag (ALS Code Ag-OG62), and by Atomic Absorption Spectroscopy (AAS) for Cu (ALS Code Cu-AA62) and Zn (ALS Code Zn-AA62). Gold was analyzed using 30gram fire assay with Atomic Absorption Spectroscopy (ALS Code Au-AA23). Over-limit Au (>10ppm) were conducted by 30gram fire assay with Gravimetric finish (ALS Code Au-GRA21).

Qualified Person

Mr. Greg Davison, MSc, PGeo, professional geologist and the Company's internal Qualified Person is responsible for the technical content of this press release within the meaning of National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101"), under TSX guidelines.

About Silver Spruce Resources Inc.

Silver Spruce Resources Inc. is a well-positioned Canadian junior exploration company pursuing exploration and development of the past-producing Kay Mine volcanogenic massive sulfide ("VMS") project in Arizona, USA, and the exploration of the Pino De Plata epithermal silver-base metal-gold project located in the prolific Sierra Madre Occidental region of western Chihuahua State in Mexico.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. The company seeks Safe Harbour.

Contact:

Silver Spruce Resources Inc.

Karl Boltz, President & CEO, Director

Toll Free: (866) 641-3397

info@silverspruceresources.com

www.silverspruceresources.com

View News Release in PDF Format:

Silver Spruce Receives Second Round of Assays from Kay Mine Development Rock Sampling, Arizona, USA

March 14, 2018